What is the name of the line cut by PCB board? What is the name of the line cut by PCB board?

2023-06-02 14:09:06

Hits: 110

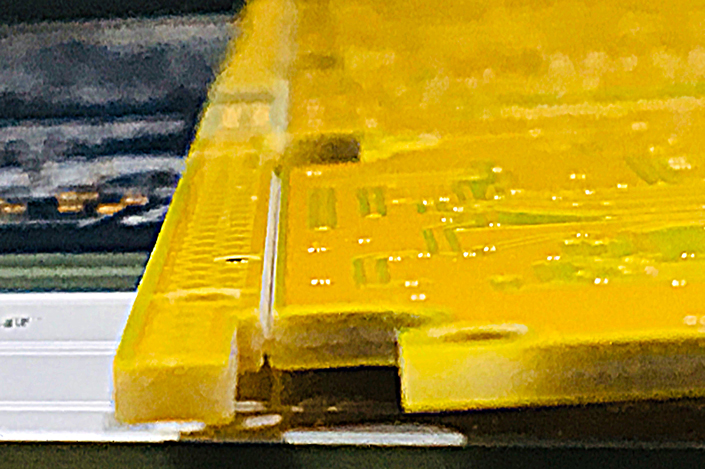

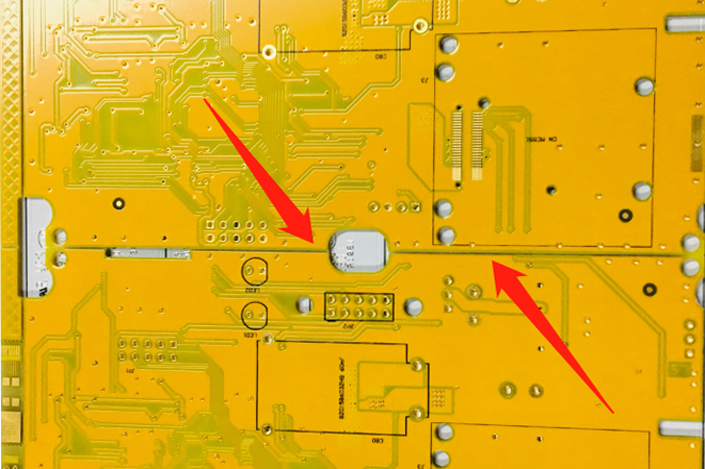

There are two common ways to cut the circuit board, one is called V-Cut (also called V-score), and the other is called stamp connecting hole.

The so-called V-Cut is a line cut by the circuit board factory at the specific position of PCB in advance according to the customer's drawing requirements. Its purpose is to facilitate the subsequent SMT circuit board assembly for De-panel. Its origin is that its cut appearance looks like an English "V".

Why do you want to design V-Cut on the circuit board? The reason is that the circuit board itself has certain strength and hardness, so it is necessary to have such pre-cut V-Cut lines to facilitate the operator to cut the original mosaic into veneers smoothly, which is the aforementioned splitting.

The purpose of designing V-cut and the operation of V-Cut dividing board

The main purpose of designing V-cut is to help operators to separate boards after the circuit board is assembled. When PCBA divides boards, the V-Cut splitter is generally used to align the V-shaped groove cut in advance on the PCB with the circular blade of Scoring, and then push it hard. Some machines have the design of automatic board feeding. As long as a button is pressed, the blade will automatically move and cross the position of the circuit board V-Cut to cut off the board, and the height of the blade can be adjusted up and down to meet the thickness of different V-cuts.

It is worth noting that PCBA boards can be divided in other ways besides V-Cut Scoring, such as Routing and stamp holes.

Although the V-Cut on the PCB can also be broken or broken manually, it is strongly recommended not to break or break the V-Cut manually, because it will bend the PCB due to the point of application, which is very easy to cause the electronic parts on the PCB to break, especially the capacitive parts, thus reducing the yield and reliability of the product. Some problems will even gradually emerge after a period of use.

Limitations of V-Cut design and use

First of all, V-Cut can only cut a straight line, and it can only be cut to the end, that is to say, V-Cut can only be cut into a straight line from beginning to end, and it can't turn to change direction, nor can it cut a short section like a tailor's line and then jump off a short section.

This is because the groove of V-Cut is cut by using the chainsaw of the upper and lower discs, and because the cutting of PCB is very precise (calculated in millimeters), it is impossible to return the cutter in half. In fact, it is not impossible, but there is no need to go to great trouble to do so. We just have to give up the process of V-Cut splitting and use Routing to cut the board. Therefore, if it is a complicated cutting path, the Routing machine will be used to split the board.

Secondly, the thickness of PCB is too thin to make V-Cut groove. Generally, if the thickness of the board is less than 1.0mm, V-Cut is not recommended, because V-Cut groove will destroy the structural strength of the original PCB. When heavy parts are placed on the board with V-Cut design, the board will be easy to bend because of gravity, which is very unfavorable for SMT welding (easy to cause empty welding or short circuit).

In addition, when the PCB passes through the high temperature of the reflow oven, the board itself will soften and deform because the high temperature exceeds the glass transition temperature (Tg). If the V-Cut position and groove depth are not well designed, the PCB deformation will be more serious, which is not conducive to the secondary reflow process.

Design and suggestion of residual thickness of V-Cut

Generally speaking, when we define the groove size of V-Cut, we will only define its Remained thickness, that is, the thickness of the plate left between the two inverted V-openings of the V-Cut groove, because this thickness determines whether the plate is easily broken and the severity of deformation.

The most common V-Cut residual thickness is suggested to be 1/3 of the thickness of the board, but the minimum thickness is not recommended to be less than 0.35 mm. If it is thinner, the board will easily break in advance in the process. The maximum thickness of V-Cut is not recommended to be greater than 0.8 mm. If it is thicker, the V-Cut cutting machine (Scoring) may not be able to completely cut it at one time, and it will also increase the damage degree of the V-Cut cutting machine blade and reduce its service life.

Angle definition of V-Cut

Finally, it is the definition of V-shaped included angle of V-Cut. Generally speaking, V-Cut can be defined in three angles: 30, 45 and 60, and the most commonly used angle is 45.

The larger the angle of the V-Cut, the more boards are eaten by the V-Cut, and the lines on the opposite PCB must be shrunk inward to avoid being cut by the V-Cut or being damaged when cutting the V-Cut.

The smaller the angle of V-Cut, the better the space design of PCB in theory, but it is not good for the life of V-Cut saw blade in PCB factory, because the smaller the angle of V-Cut, the thinner the blade of chainsaw will be, and the easier it is to wear and break its blade. In addition, the thicker the board is, the larger the V-Cut angle is because it must be cut deeply. If the board thickness is more than 1.6mm, the board factory is usually unwilling to accept the V-Cut angle of 30, unless you are big enough, you can use the Router cutting design instead. Since Router cutting can solve almost all the disadvantages caused by V-Cut cutting, why design V-Cut? Because the price is different! This is the world, there is absolutely nothing cheap and easy to use.

■ Hot News